Industrial Automation & Control Systems

Due to the rapid advances in technology, all industrial processing systems, factories, machinery, test facilities, etc. turned from mechanization to automation. A mechanization system needs human intervention to operate the manual operated machinery. As new and efficient control technologies evolved, computerized automation control is being driven by the need for high accuracy, quality, precision and performance of industrial processes.

Automation is a step beyond the mechanization which makes use of high control capability devices for efficient manufacturing or production processes.

What is Industrial Automation

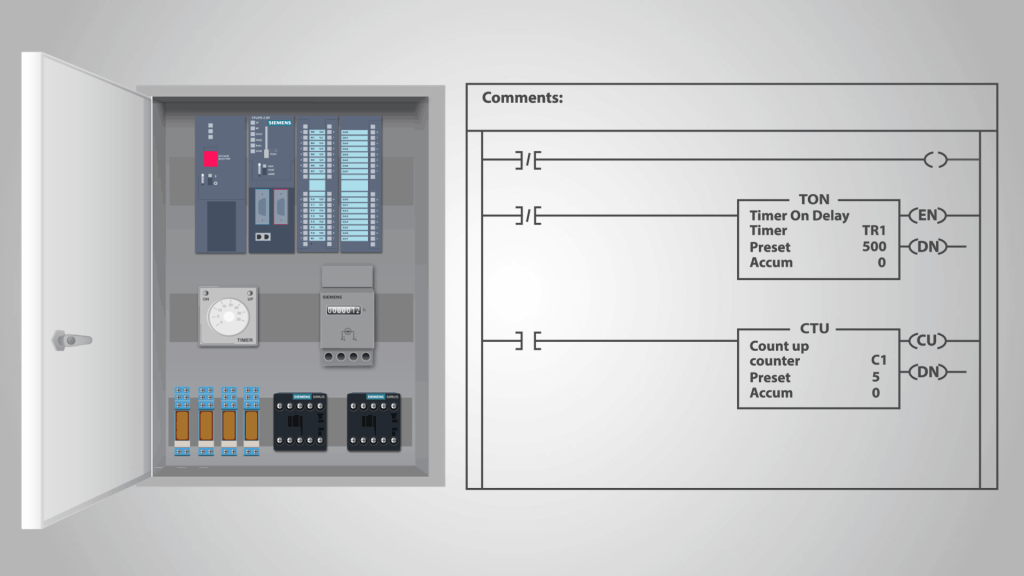

Industrial automation is the use of control devices such as PC/PLCs/PACs etc. to control industrial processes and machinery by removing as much labor intervention as possible, and replacing dangerous assembly operations with automated ones.

Automation is a broad term applied to any mechanism that moves by itself or is self-dictated. As compared with manual systems, automation systems provide superior performance in terms of precision, power, and speed of operation.

In industrial automation control, a wide number of process variables such as temperature, flow, pressure, distance, and liquid levels can be sensed simultaneously. All these variables are acquired, processed and controlled by complex microprocessor systems or PC based data processing controllers.

Control Systems are an essential part of an automation system. The various types of closed-loop control techniques ensure the process variables to follow the set points. In addition to this basic function, the automation system employs different other functions such as computing set points for control systems, plant startup or shutdown, monitoring system performance, equipment scheduling, etc. The control systems combined with monitoring adapted to the operating environment in the industry allow for a flexible, efficient and reliable production system.

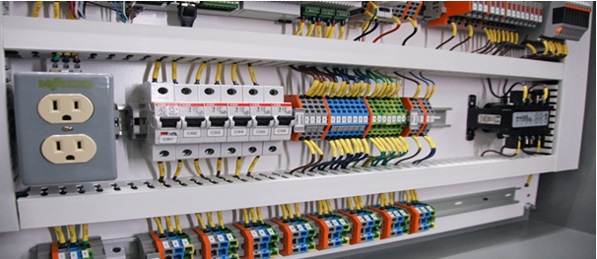

The automated system needs special dedicated hardware and software products for

implementing control and monitoring systems.

Advantages of Industrial Automation

Manufacturers face many challenges in today’s globally competitive business landscape. Some of these challenges include harsh manufacturing environments (in a world which is increasingly focused on safety – and rightly so), increasingly complex supply chains, meeting the latest energy efficient standards, and competing with companies with very small marginal costs.

The advantages to Industrial Automation include:

- Increased labor productivity

- Improved product quality

- Reduced labor or production cost

- Reduced routine manual tasks

- Improved safety

- Assisted remove monitoring

At BM Investments Ltd, we offer a variety of Control Systems solutions for Factories in Rwanda and East Africa.

Schedule An Automated Control System Site Visit

When scheduling an Automated control system installation throughout Rwanda, East Africa, you want to be sure you choose a reliable company. We can help you get the job done in a timely and efficient manner.

Contact us now to discuss Control Systems and Automation for your organization!